Related Products

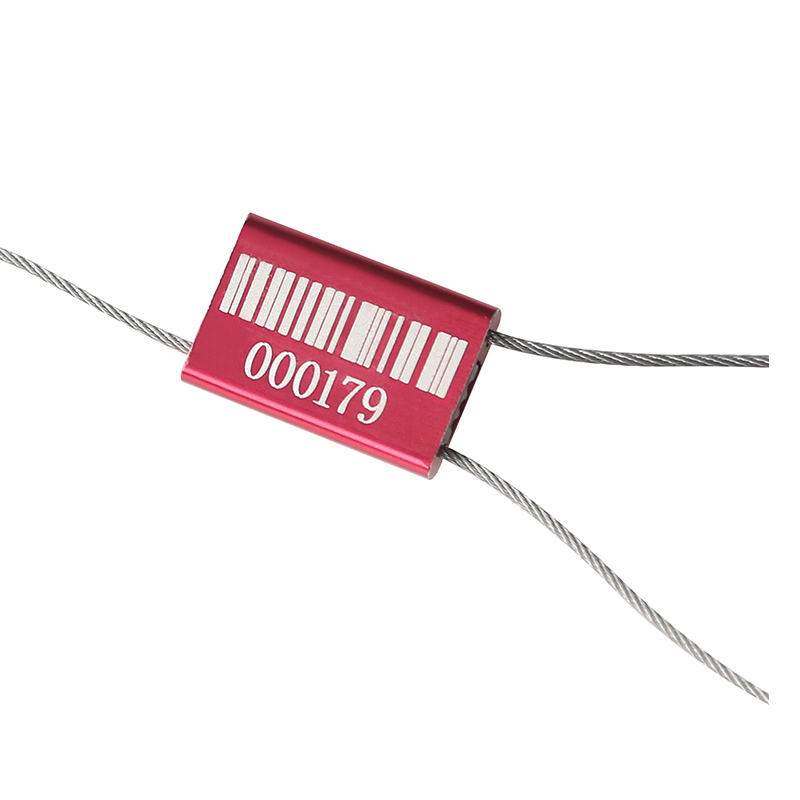

| Model No.: | WJ-N1.5 |

|---|---|

| MOQ: | 1000 pcs |

| Material: | Alluminum alloy |

| Delivery Time: | 5 days |

| Payment: | T/T,LC,Western Union |

| Loading Port: | Ningbo or Shanghai Port,China |

| Printing: | Logo & Number |

| Color: | Available in any color |

Copyright © 2025 Yongjia Liaoseal Co.,Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a responsefrom us via email. Please be sure to leave yourcontact details so that we can better assist